BEGIN WITH THE BEST

While oil purification is effective with any compressor fluid, maximum oil life is only achieved by beginning with the best, most advanced, compressor fluid available. PuroLube PAG 16K is a long life (16,000 hour rated), non-varnishing PAG/POE full synthetic with user-optimized and replenishable additive system that delivers maximum protection, service life and value.

TAKING PERFORMANCE TO THE NEXT LEVEL

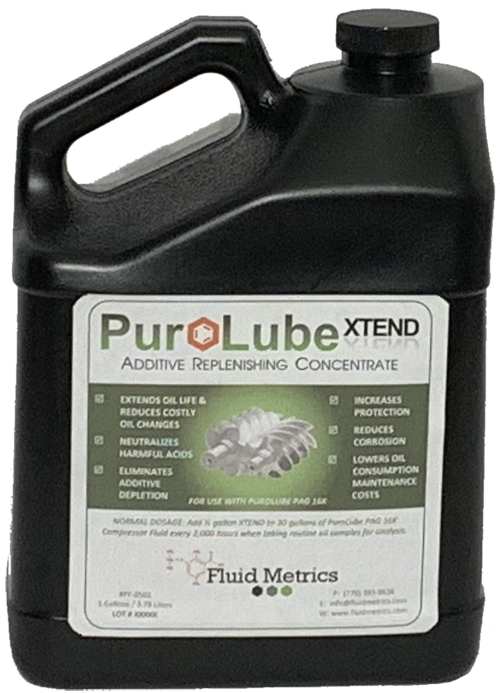

All air compressor fluids are fortified with essential additives to enhance fluid performance and service life. During normal compressor operation, these additives continuously deplete to accelerate fluid degradation, acid production, and corrosion. PuroLube XTEND Additive Replacement Concentrate contains the same state-of-the-art additives used in PuroLube and can be added whenever additive levels get low to restore fluid chemistry, performance and protection, and further extend fluid service life.

TAKING PERFORMANCE TO THE NEXT LEVEL

Acids may be ingested from the atmosphere or the normal byproduct of oxidation. They are harmful to compressor fluids and the internals they are designed to protect. Allowed to accumulate in the oil, acids are catalysts that accelerate oil degradation and corrosion. Additionally, acids reduce the useful life of compressor fluids, bearings, coolers and all oil-wetted components. Fluid Metrics’ award-winning COP with patented ion exchange technology proactively and continuously removes harmful acids from the oil. It provides maximum protection and service life to the oil and expensive compressor internals. Rotary Screw compressors using a COP routinely exceed 30,000 hours oil life when operating in normal environments.

THE ULTIMATE IN PROTECTION, RELIABILITY & SAVINGS

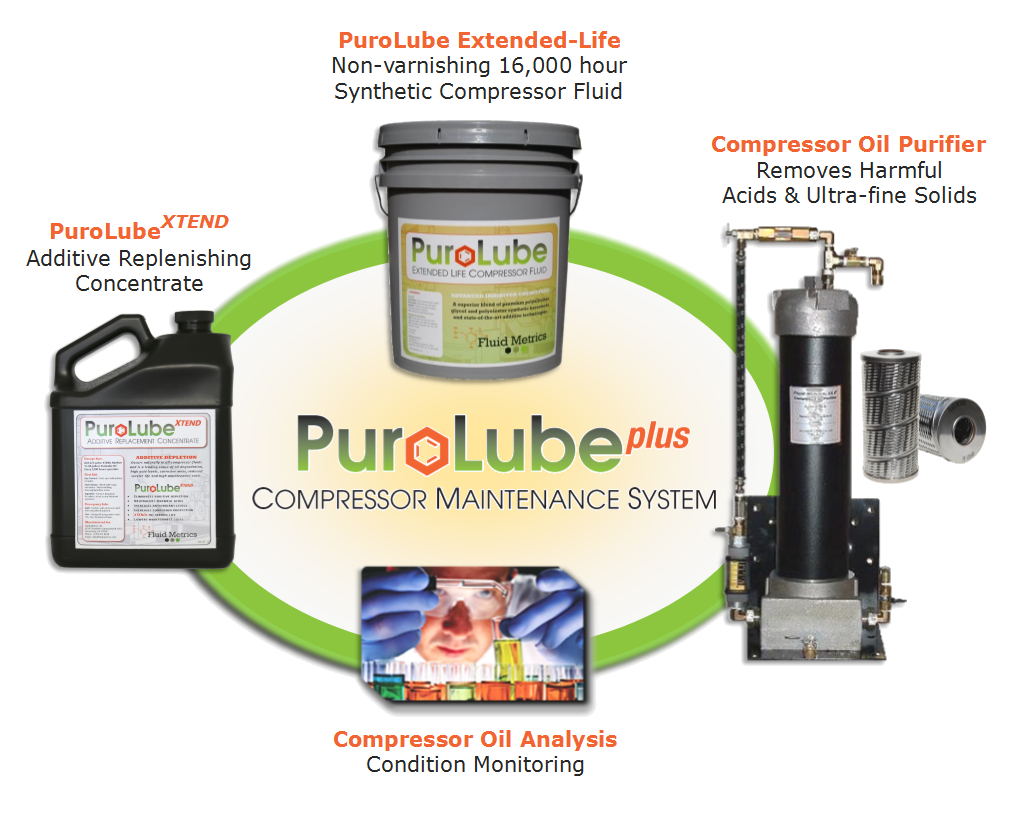

Finally, the Fluid Metrics’ PuroLube PLUS Compressor Maintenance System provides compressor users with the ultimate in protection, reliability and savings. PuroLube PLUS combines our PuroLube Extended-life Compressor Fluid. It is the industry’s longest-life non-varnishing synthetic compressor fluid, “PLUS” our award-winning COP that continuously purifies the oil from harmful acids and ultra-fine solids, “PLUS” independent Oil Analysis for accurate and reliable condition monitoring, “PLUS” our PuroLube XTEND Additive Replenishing Concentrate to maintain the oil’s protective additives at healthy new oil levels.

As a result, we are unlike the outdated “Preventative” (oil & parts changing) maintenance promoted by the OEMs. PuroLube PLUS is a state-of-the-art, proactive, part of reliability-centered maintenance. It specifically targets the root causes of most routine compressor maintenance and repairs. PuroLube PLUS combines The Best Available fluid conditioning and maintenance technologies into a simple, easy-to-use system that does the work for you and frees up time and money to be used elsewhere.

Long-life, non-Varnishing Synthetic Compressor Oil.

Ion Exchange Acid Adsorption

Ultra-fine Filtration.

Oil Analysis Condition Monitoring.

Additive Replenishment.

Maximizes Reliability and Oil & Separator Life.

Minimizes Oil Change Frequency, Consumption & Disposal.

Reduces Environmental Impact.

Reduces Maintenance Labor & Downtime.

Saves Time & Money.

Fluid Metrics PuroLube Maintenance for Air Compressor System

Ready to put our PuroLube system to the test on your air other type of compressor? Contact us to get in touch with our team and learn more.