3 COP MODELS

Design & Installation

1. COP-60

2. COP-30

3. COP-10

First of all, the revolutionary Compressor Oil Purifier (COP) goes beyond a standard compressed air oil filter. It was specifically designed to meet the unique challenges presented by oil-flooded rotary screw air compressors. The COP is available in 3 sizes to fit most any size compressor and application.

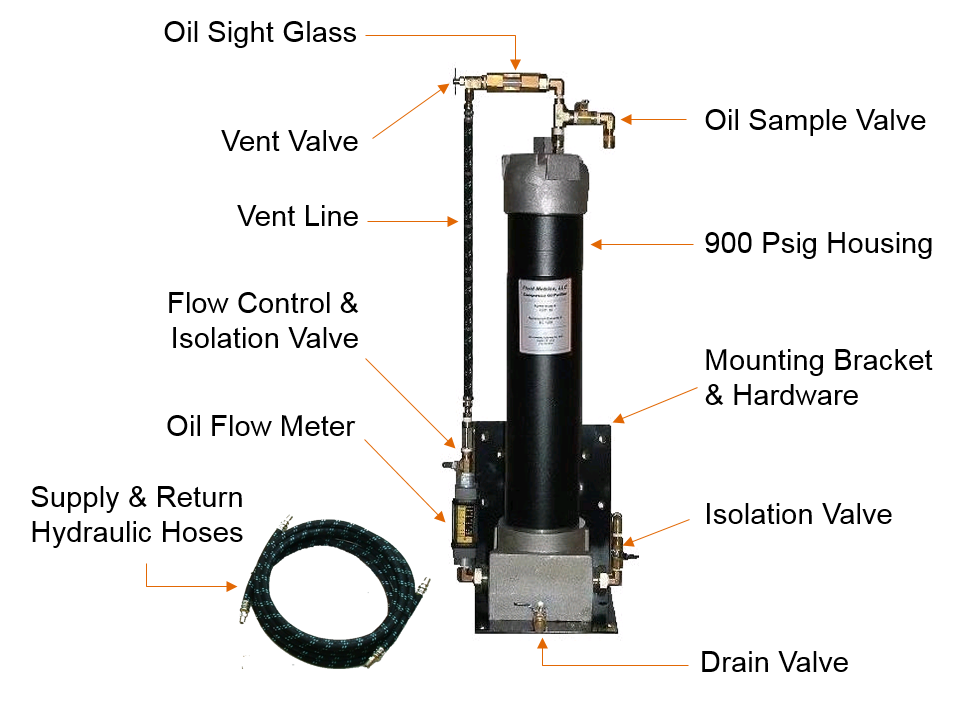

Each COP comes complete with a 900 psig rated housing and an installation kit that includes all the hardware and accessories needed for a quick and easy installation. Its compact vertical design allows the COP to be installed inside or outside most compressor enclosures.

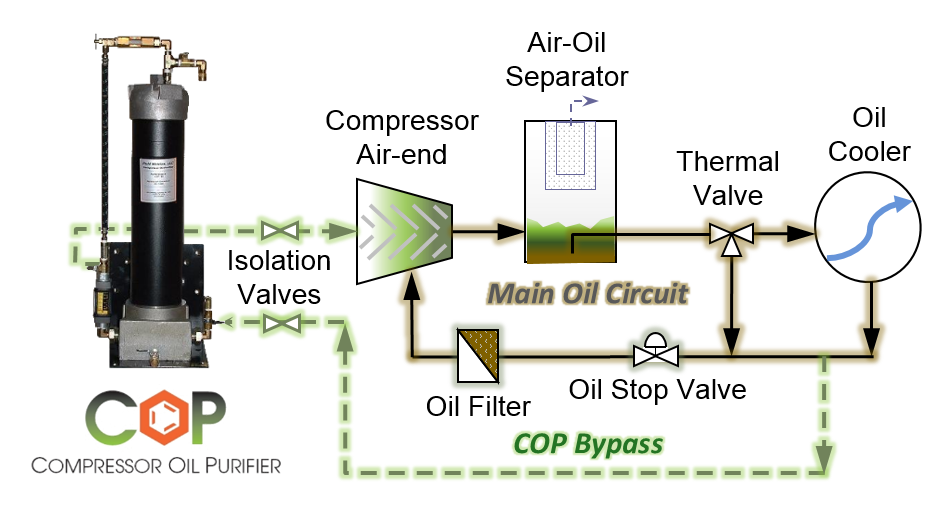

Additionally, the COP is a low flow “bypass” device that installs in an auxiliary loop to the compressor’s main oil circuit. This bypass design allows the COP to be isolated and its purification elements easily replaced without having to shut down the compressor.

The COP continuously purifies a small slip-stream of oil circulated by oil pressure supplied by the compressor. No pump or electricity is needed making the COP a snap to install.

Low Flow Bypass Design

- Includes Installation Kit with all necessary Accessories.

- Quick & Easy to Install.

- Can be Located Inside or Outside Compressor Enclosure.

- Easily Isolated to Replace Elements without having to Shut Down the Compressor.

- Finally, Low Flow Bypass Design Does Not Interfere with Main Oil Circuit.

Installation Kit

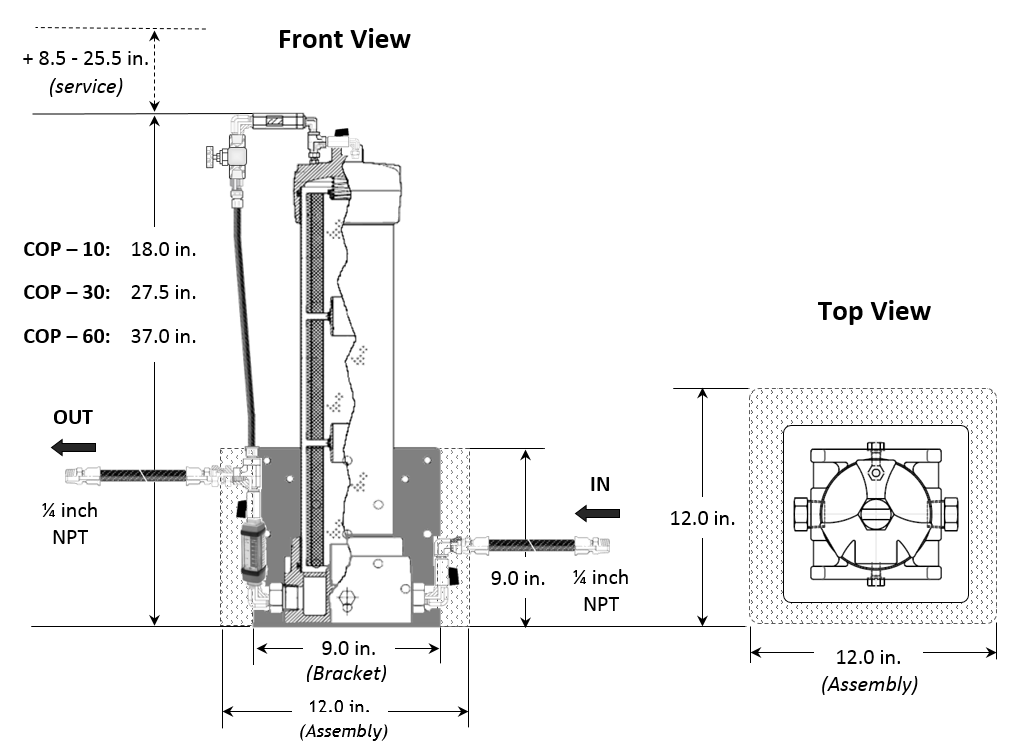

Dimensions