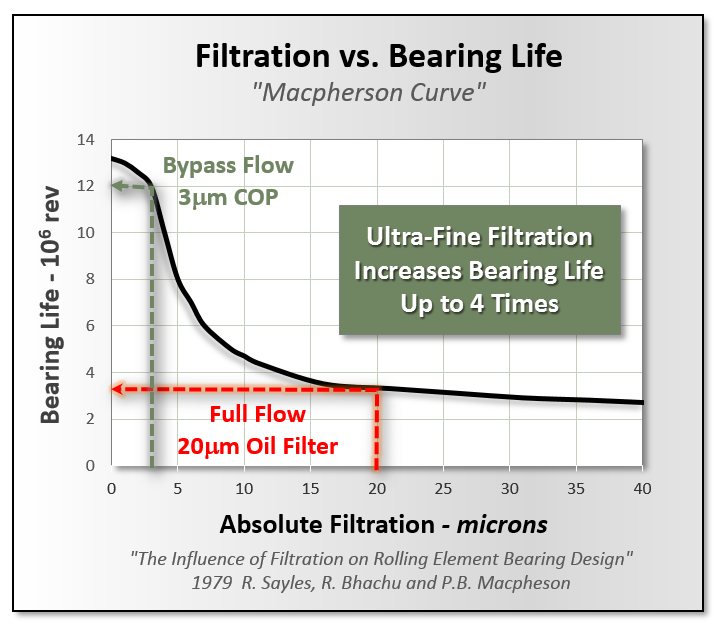

Ultra-fine solids found in compressor fluids are the root cause of bearing wear and fouling of the compressor’s air-oil separators. They help drive up your maintenance costs. By design, most OEM “full-flow” oil filters are only sized to remove solids down to 20 microns. As result, this leaves the smaller more destructive “clearance-size” solids to remain in the oil to be constantly circulated and spread their damage to other critical components. Our Ultra-Fine Air Compressor Filter & Oil Filtration is designed to combat this all.

By comparison, Fluid Metrics’ COP is a low-flow “bypass” device that uses ultra-fine filtration to continuously remove ultra-fine solids down to 3 microns (Beta > 200). It prevents them from accumulating in the oil. Studies have shown that improving oil filtration down to 3 microns can improve bearing life up to 4 times over standard coarse, full-flow filtration. Fewer solids in the oil and lower ISO Particle Counts is also proven to reduce separator fouling. Thus, there is a resulting increase in pressure drop and compressor energy consumption.

- Continuously Removes Ultra-fine Solids.

- Reduces Bearing Wear & Separator Fouling.

- Reduces Metal Catalysts & Oxidation Rates.

- Increases Oil, Bearing & Separator Life.

- Increases Protection & Reliability.

- Reduces ISO Particle Counts.

- Reduces Maintenance, Repairs & Downtime.

- Reduces Oil & Separator Changes & Disposal.

- Reduces Environmental Impact.

- Saves Time & Money.

Fluid Metrics Ultra Fine Air Compressor Filter Sytem

Ready to give our filtration system a change? Contact us to get in touch with our team and learn more.